Value Delivered

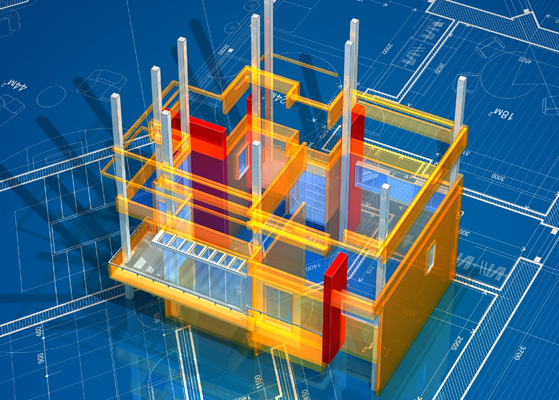

We provided HVAC, plumbing, and process piping solutions for this expansion project. We used building information modeling (BIM) to ensure constructability, which helped us complete the work in a timely manner to the satisfaction of the owner and general contractor.

Client Objectives

Gilead needed to build out an existing space at their Oceanside, CA facility and convert it into a new vector manufacturing facility. The project required complex HVAC, mechanical, and process piping systems. The customer turned to us for our expertise in BIM.

Solutions

For this project, we:

- Installed ten custom air handling units, seven of which served cleanroom spaces, 14 high plume dilution fans, and eight blower sets

- Set and installed ambient water for injection (AWFI) generation skid and AWFI piping with 11 use and sample points

- Built exterior bottle storage area for liquid nitrogen, nitrogen, oxygen, and carbon dioxide, and installed switchover manifolds and distribution piping throughout the facility

- Installed lab waste piping, domestic plumbing, sanitary waste piping, industrial plumbing, liquid nitrogen vacuum-jacketed piping, and water softeners

Client Background

Gilead Sciences is an American biopharmaceutical company with global operations dedicated to developing innovative medicines for life-threatening illnesses.